- Thick Copper PCB Capability

- PCB manufacturing equipment

Introducing Thick Copper PCB, the high-performance solution designed to handle high currents and provide exceptional thermal management. Thick Copper PCBs are specifically engineered with a thicker copper layer compared to standard PCBs, offering enhanced conductivity, power handling, and heat dissipation capabilities.

Our Thick Copper PCBs are constructed using premium materials and advanced manufacturing techniques. The increased copper thickness allows for lower resistance, reducing voltage drop and ensuring efficient power delivery. This makes Thick Copper PCBs ideal for applications that require high current carrying capacity, such as power electronics, automotive systems, and industrial machinery.

In addition to superior conductivity, Thick Copper PCBs excel in thermal management. The thick copper layer acts as a highly efficient heat sink, dissipating heat generated by power components and preventing hotspots. This results in improved reliability and extended lifespan of the circuitry.

Furthermore, Thick Copper PCBs offer excellent mechanical strength, providing structural integrity and resistance to bending or warping. This makes them suitable for applications subject to mechanical stress or harsh operating conditions.

Thick Copper PCBs, also known as Heavy Copper PCBs or Power Copper PCBs, are specialized printed circuit boards with copper traces and planes that have greater thickness compared to standard PCBs. These boards are designed to handle higher current loads and provide enhanced power distribution capabilities. Here are some key considerations regarding the capability of Thick Copper PCBs:

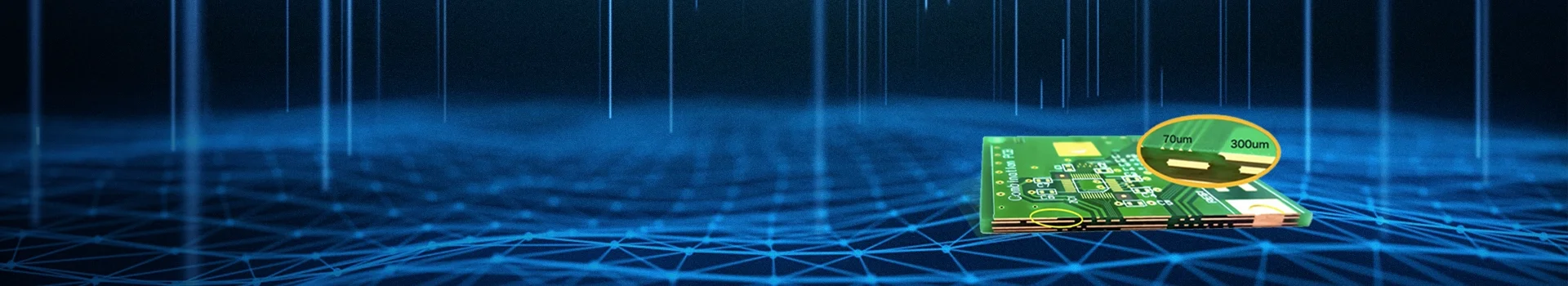

- Copper Thickness: Thick Copper PCBs typically have copper thicknesses ranging from 2 ounces (70 µm) to 20 ounces (700 µm) or even higher. The increased copper thickness allows for improved current carrying capacity and reduced resistive losses.

- Current Carrying Capacity: Thick Copper PCBs are designed to handle higher current loads compared to standard PCBs. The increased copper thickness helps to minimize voltage drops and dissipate heat generated by high-power components.

- Power Distribution: Thick Copper PCBs excel in power distribution applications, such as power supplies, motor controllers, high-power amplifiers, and industrial equipment. The thick copper traces and planes enable efficient power delivery and reduce thermal issues.

- Heat Dissipation: Thick Copper PCBs can dissipate heat more effectively due to the increased copper mass. The copper acts as a heat sink, spreading heat away from hotspots and enhancing thermal management.

- Design Considerations: Designing Thick Copper PCBs requires careful consideration of various factors, including trace widths, spacing, thermal management, and mechanical stability. The increased copper thickness affects the required trace widths to handle specific currents and the clearance requirements to avoid short circuits.

- Manufacturing Techniques: Thick Copper PCBs require specialized manufacturing techniques to achieve the desired copper thickness. This may include multiple plating and etching processes, as well as the use of additional layers or laminations. PCB manufacturers experienced in Thick Copper PCB fabrication can provide the necessary expertise.

- Cost Considerations: Thick Copper PCBs are generally more expensive compared to standard PCBs due to the higher copper content and additional manufacturing steps involved. The cost will depend on the copper thickness, board size, complexity, and quantity.

- PCB Layer Count: Thick Copper PCBs can be designed as single-sided, double-sided, or multilayer boards. The layer count depends on the specific requirements of the application, including signal integrity, power distribution, and thermal management.

Advantages:

- High Current Capability: Thick Copper PCBs are designed to handle high currents, ensuring efficient power delivery and minimizing voltage drop.

- Enhanced Thermal Management: The thick copper layer acts as a highly efficient heat sink, dissipating heat and preventing hotspots, thereby improving reliability and prolonging component lifespan.

- Improved Power Efficiency: Lower resistance due to increased copper thickness reduces power losses. This also results in higher power efficiency and reduced energy consumption.

- Mechanical Stability: Thick Copper PCBs provide excellent mechanical strength and resistance to bending or warping. This makes them suitable for applications subject to mechanical stress.

- Wide Range of Applications: Thick Copper PCBs are used in power electronics, automotive systems, renewable energy systems, and industrial machinery, where high current carrying capacity and efficient heat dissipation are critical.

| Thick Copper PCB Capability | |

| Feature | Capability |

| Material | FR-4 Standard Tg 140°C, FR4-High Tg 170°C |

| Min. Track/Spacing | For External layers: 4oz Cu 10mil/13mil,5oz Cu 12mil/15mil 6oz Cu 15mil/15mil |

| For Internal layers: 4oz Cu 8mil/8mil,5oz Cu 10mil/10mil 6oz Cu 12mil/12mil |

|

| Min. Hole Size | 0.15 ~ 0.3mm |

| Max Outer Layer Copper Weight (Finished) | 13oz |

| Max Inner Layer Copper Weight | 12oz |

| Board Thickness | 0.6-6mm |

| Surface Finishing | HASL lead free,Immersion gold, OSP, Hard Gold,Immersion Silver,Enepig |

| Solder Mask | Green, Red, Yellow, Blue, White, Black, Purple, Matte Black, Matte green |

| Silkscreen | White, Black |

| Via Process | Tenting Vias,Plugged Vias,Vias not covered |

| Testing | Fly Probe Testing (Free) and A.O.I. testing |

| Build time | 5-15 days |

| Lead time | 2-3 days |

PCB Drilling machine

PCB pattern plating line

PCB pattern plating line

PCB pattern expose machine

Strip film etching line

Solder mask screen silk print machine

Solder mask screen silk print machine

PCB Flying Probe Test (FPT)

Fully automatic exposure machine