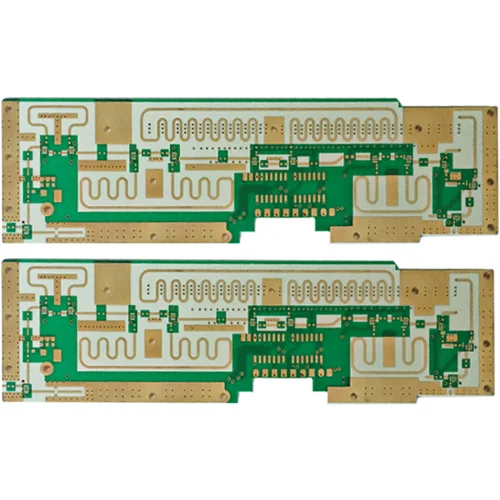

Rogers RT5870 High Frequency Board

Product Name: Rogers RT5870 High Frequency Board

Product Type: Rogers RT/duroid 5870 high frequency board

Material: Rogers RT/duroid 5870

Number of layers/plate thickness: 2 layers/0.9mm

Line width/line spacing: 0.762mm

Application areas: commercial aerospace broadband antennas, microstrip lines and strip circuits, millimeter wave equipment, radar systems, missile guidance systems, point-to-point digital radio frequency antennas

Rogers RT5870 High Frequency Board

Name: Rogers RT5870 High Frequency Board

Material: Rogers RT5870

Layer: 2L

DK: 2.33

Dielectric Thickness: 0.762mm

Thermal Conductivity: 0.69w/m.k

Volume Resistivity: 1.2*1010

Surface Resistivity: 5.7*109

Finished Thickness: 0.85MM

Surface Treatment: Immersion Gold

Application: Commercial avionics pcb, microstrip and stripline pcb, millimeter wave applications pcb, missile

Name: Rogers 4003 PCB

Material: Rogers 4003 material

rogers 4003 dielectric constant: 3.38

Layer: 4003+4450F

rogers 4003 thickness: 0.508mm(20mil)

Finished Thickness: 2.0mm

Rogers 4003 substrate Copper Thickness: 17μm

Finished Copper Thickness: 1OZ

SurfaceTreatment: Immersion Gold

Color:Green /White

Min Trace / Space: 6mil/6mil

Features: Rogers PCB, tg280 high temperature resistant PCB

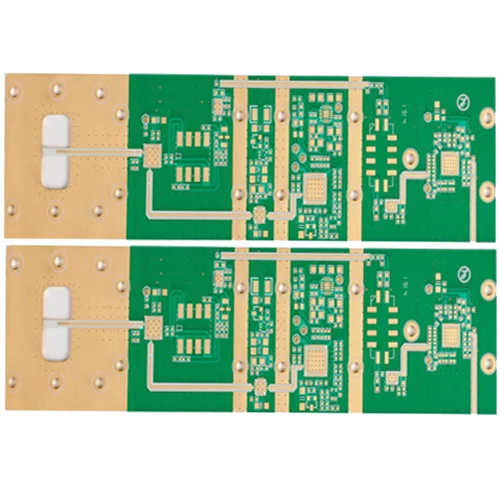

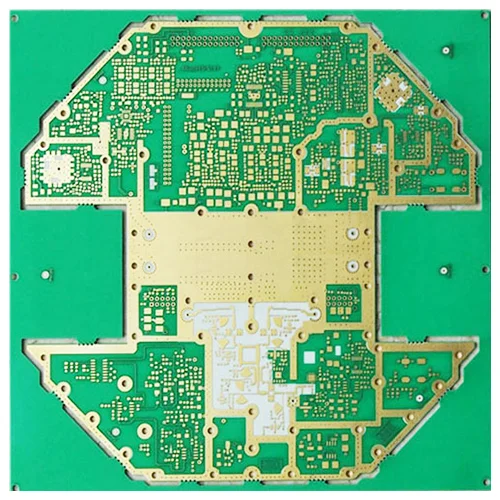

PCB high frequency microwave hybrid PCB

Name: PCB high frequency microwave hybrid plate

Layers: 6 layers

Plate thickness: 1.6±0.14mm

Plate used: Rogers4350B+FR4 Shengyi

Dielectric constant: 2.2±0.02

Dielectric loss factor: 0.0009

Z small aperture: 0.3mm

Surface Treatment: Immersion Gold ENIG

Z line width/spacing: 0.2mm/0.3mm

Process features: special materials, Rogers4350B+FR4 Shengyi mixed lamination

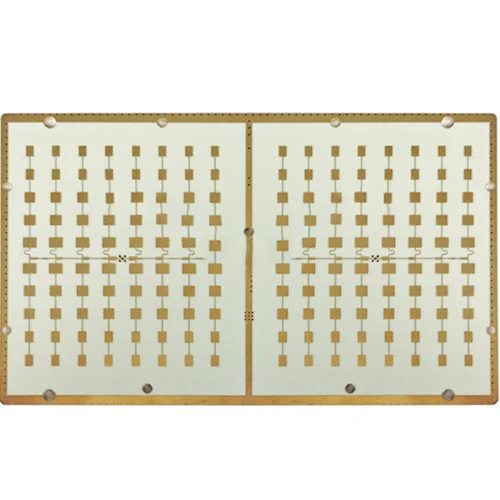

Name: Rogers Printed Circuit Board(PCB)

Material: rogers PCB material

Quality standard: IPCB6012 Class2 or Class3

Rogers PCB material dielectric constant: 2.2-16

the texture of material: rogers ceramic PCB

Layers: 1layer – multilayer hybrid PCB

Thickness: 0.1mm – 12mm

Copper thickness: 0.5oz – 3oz

Surface technology: Silver, Gold, OSP

Application: High frequency rogers microwave PCB

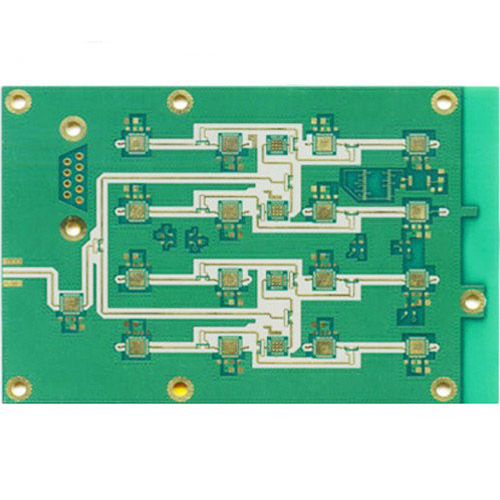

Rogers RO4003C High Frequency PCB Board

Name: Rogers RO4003C High Frequency PCB Board

Darkness: 3.38±0.04

Layers: 2 layers

Dielectric thickness: 0.508mm (20mil)

Finished thickness: 0.6mm

Material Copper Thickness: ½(17μm)

Finished copper thickness: 1OZ (35μm)

Surface treatment: Immersion silver

Applications: Communication infrastructure, computers, aerospace

- PCB Capability

- PCB manufacturing equipment

- PCB Materials

Introducing Rogers PCB, the epitome of high-performance printed circuit boards. Rogers PCBs are crafted using Rogers Corporation’s advanced materials, known for their exceptional electrical properties, thermal stability, and reliability. These PCBs are the preferred choice for applications that demand high-frequency performance, such as RF and microwave circuits.

Our Rogers PCBs are engineered with a specialized laminate that combines a low-loss dielectric material with high thermal conductivity. This unique construction ensures minimal signal loss, excellent signal integrity, and efficient heat dissipation, making them ideal for high-speed and high-power applications.

With their superior electrical characteristics, Rogers PCBs provide reliable performance in complex circuits, such as antennas, amplifiers, and radar systems. Their low loss tangent and controlled impedance enable precise signal transmission, minimizing distortion and maximizing signal quality.

Rogers PCBs are also known for their stability over a wide range of temperatures. This also ensures a consistent performance even in extreme environmental conditions. They exhibit excellent dimensional stability, reducing the risk of warping or delamination during manufacturing or operation.

Advantages:

- High-Frequency Performance: Rogers PCBs excel in high-frequency applications, offering low signal loss and controlled impedance for precise signal transmission.

- Excellent Signal Integrity: These PCBs also ensure minimal distortion, maintaining signal quality and enabling reliable operation of high-speed circuits.

- Efficient Thermal Management: Rogers PCBs have high thermal conductivity, allowing for effective heat dissipation, ensuring the integrity and longevity of components.

- Wide Temperature Range: Rogers PCBs exhibit stability over a broad temperature range, ensuring consistent performance in various environmental conditions.

- Reliable and Durable: These PCBs are known for their reliability and also durability, making them suitable for mission-critical applications that require long-term performance.

| Item | Capability |

| Layer Count | 1-40layers |

| Base Material | KB、Shengyi、ShengyiSF305、FR408、FR408HR、IS410、FR406、GETEK、370HR、IT180A、Rogers4350B、Rogers4000、PTFE Laminates(Rogers series、Taconic series、Arlon series、Nelco series)、Rogers/Taconic/Arlon/Nelco laminate with FR-4 material(including partial Ro4350B hybrid laminating with FR-4) |

| Board Type | Backplane、HDI、High multi-layer 、blind&buried PCB、Embedded Capacitance、Embedded resistance board 、Heavy copper power PCB、Backdrill. |

| Board Thickness | 0.2-5.0mm |

| Copper Thickness | Min. 1/2 OZ, Max. 10 OZ |

| PTH Wall | 25um(1mil) |

| Maximum Board Size | 1100*500mm(43”*19”) |

| Min laser drilling size | 4mil |

| Min. Spacing/Tracing | 2.7mil/2.7mil |

| Solder Mask | Green, Black, Blue, Red, White, Yellow, Purple matte/glossy |

| Surface Treatment | Flash gold(electroplated gold)、ENIG、Hard gold、Flash gold、HASL Lead-free 、OSP、ENEPIG、Soft gold、Immersion silver、Immersion Tin、ENIG+OSP, ENIG+Gold finger, Flash gold(electroplated gold)+Gold finger, Immersion silver+Gold finger, Immersion Tin+Gold finger. |

| Min. Annular Ring | 3mil |

| Aspect ratio | 10:1(HASL Lead-free 、HASL Lead、ENIG、Immersion Tin、Immersion silver、ENEPIG);8:1(OSP) |

| Impedance control | ±5ohm(<50ohm), ±10%(≥50ohm) |

| Other Techniques | Blind/Buried Via |

| Gold Fingers | |

| Press Fit | |

| Via in Pad | |

| Electrical Test |

PCB Drilling machine

PCB pattern plating line

PCB solder mask expose machine

PCB pattern expose machine

Strip film etching line

Solder mask screen silk print machine

Solder mask scrubbing line

PCB Flying Probe Test (FPT)

Fully automatic exposure machine

| Here there’re many laminate material datasheets, they’re useful and helpful for you, please see them: | ||||||||

| SUPPLIER | PCB LAMINATE | TYPE | MATERIAL DATASHEET | TG | TD | DK(1MHZ) | DK(1GHZ) | DK(10GHZ) |

| KB | KB-6160 | FR4 | DOWNLOAD | 135 | 305 | 4.35 | – | – |

| KB-6160A | FR4 | DOWNLOAD | 135 | 305 | 4.35 | – | – | |

| KB-6160C | FR4 | DOWNLOAD | 135 | 314 | 4.7 | – | – | |

| KB-6150 | FR4 | DOWNLOAD | 132 | 305 | 4.6 | – | – | |

| KB-6150C | ||||||||

| KB-6164 | FR4 | DOWNLOAD | 142 | 330 | 4.8 | – | – | |

| KB-6164F | FR4 | DOWNLOAD | 145 | 340 | 4.8 | – | – | |

| KB-6165F | FR4 | DOWNLOAD | 150 | 346 | 4.8 | – | – | |

| KB-6167F | FR4 | DOWNLOAD | 170 | 349 | 4.8 | – | – | |

| SHENGYI | S1141 | FR4 | DOWNLOAD | 135 | 310 | 4.6 | – | – |

| S1141KF | FR4 | DOWNLOAD | 140 | 350 | 4.7 | – | – | |

| S1000 | FR4 | DOWNLOAD | 155 | 335 | 4.9 | – | – | |

| S1170 | FR4 | DOWNLOAD | 170 | 335 | 4.6 | – | – | |

| S1000-2 | FR4 | DOWNLOAD | 170 | 335 | 4.8 | – | – | |

| S1155 | FR4 | DOWNLOAD | 135 | 370 | 4.7 | – | – | |

| ITEQ | IT-158 | FR4 | DOWNLOAD | 150 | 340 | 4.6-4.8 | – | – |

| IT-180 | FR4 | DOWNLOAD | 180 | 350 | 4.5-4.7 | – | – | |

| TUC | TU-768 | FR4 | DOWNLOAD | 180 | 350 | – | 4.3-4.4 | 4.3 |

| TU-872 | Modified Epoxy | DOWNLOAD | 200 | 340 | – | 3.8-4.0 | 3.8 | |

| ROGERS | RO 3003 | Cer/PTFE | DOWNLOAD | – | 500 | – | – | 3 |

| RO 3010 | Cer/PTFE | DOWNLOAD | – | 500 | – | – | 10.2 | |

| RO 4003 | Hydrocarbon/Cer | DOWNLOAD | >280 | 425 | – | – | 3.38 | |

| RO 4350B | Hydrocarbon/Cer | DOWNLOAD | >280 | 390 | – | – | 3.48 | |

| RT/duroid 5880 | PTFE/Glass | DOWNLOAD | – | 500 | – | – | 2.2 | |

| ISOLA | Polyclad 370HR | FR4 | DOWNLOAD | 170 | 340 | 4.8-5.1 | – | – |

| FR406-HR | FR4 | DOWNLOAD | 190 | 325 | 3.91 | 3.86 | 3.81 | |

| FR408-HR | FR4 | DOWNLOAD | 200 | 360 | 3.72 | 3.69 | 3.65 | |

| P96 | Polyimide | DOWNLOAD | 260 | 416 | – | 3.78 | 3.73 | |

| Hitachi | MCL-BE- 67G | Modified Epoxy | DOWNLOAD | 140 | 340 | 4.9 | 4.4 | – |

| MCL-E-679F | FR4 | DOWNLOAD | 170 | 350 | 4.2-4.4 | 4.3-4.5 | – | |

| MCL-LX-67Y | Special Laminate | DOWNLOAD | 185-195 | 325-345 | – | 3.4-3.6 | – | |

| Nelco | N4000-13 | Modified Epoxy | DOWNLOAD | 210-240 | 365 | – | 3.7 | 3.6 |

| N4000-13EP | Modified Epoxy | DOWNLOAD | 210-240 | 350 | – | 3.4 | 3.2 | |

| N4000-13SI | Modified Epoxy | DOWNLOAD | 210-240 | 350 | – | 3.4 | 3.2 | |

| N4000-13EP SI | Modified Epoxy | DOWNLOAD | 210-240 | 350 | – | 3.4 | 3.2 | |

| Taconic | TLX-6 | PTFE | DOWNLOAD | – | – | – | – | 2.65 |

| TLX-7 | PTFE | DOWNLOAD | – | – | – | – | 2.6 | |

| TLX-8 | PTFE | DOWNLOAD | – | – | – | – | 2.55 | |

| TLX-9 | PTFE | DOWNLOAD | – | – | – | – | 2.45 | |

| RF35 | PTFE | DOWNLOAD | <315 | – | 3.5 | – | 3.5 | |

| TLC-27 | PTFE | DOWNLOAD | – | – | – | – | 2.75 | |

| TLC-30 | PTFE | DOWNLOAD | – | – | – | – | 3 | |

| TLC-32 | PTFE | DOWNLOAD | – | – | – | – | 3.2 | |

| Arlon | Arlon 25N | Cer | DOWNLOAD | 260 | – | – | – | 3.38 |

| Arlon 25FR | Cer | DOWNLOAD | 260 | – | – | – | 3.58 | |

| Arlon 33N | Polymide | DOWNLOAD | >250 | 353 | 4 | – | – | |

| Arlon 35N | Polymide | DOWNLOAD | >250 | 363 | 4.2 | – | – | |

| Arlon 85N | Polymide | DOWNLOAD | 250 | 387 | 4.2 | – | – | |

| Stablcor | ST325 | – | DOWNLOAD | Thermal conductivity:75w/m.k(with 1oz copper) | ||||

| ST10 | – | DOWNLOAD | Thermal conductivity:325w/m.k(with 1oz copper) | |||||

| Panasonic | R-1566W | FR4 | DOWNLOAD | 140 | 330 | 4.95 | 4.7 | 4.65 |

| Ventec | VT-901 | Polymide | DOWNLOAD | 250 | 390 | 4.2-4.5 | 4.0-4.3 | – |

| VT-90H | Polymide | DOWNLOAD | 250 | 390 | 4.2-4.5 | 4.0-4.3 | – | |

| Bergquist | ht-04503 | – | DOWNLOAD | Thermal conductivity:2.2w/m.k(with 1oz copper) | ||||