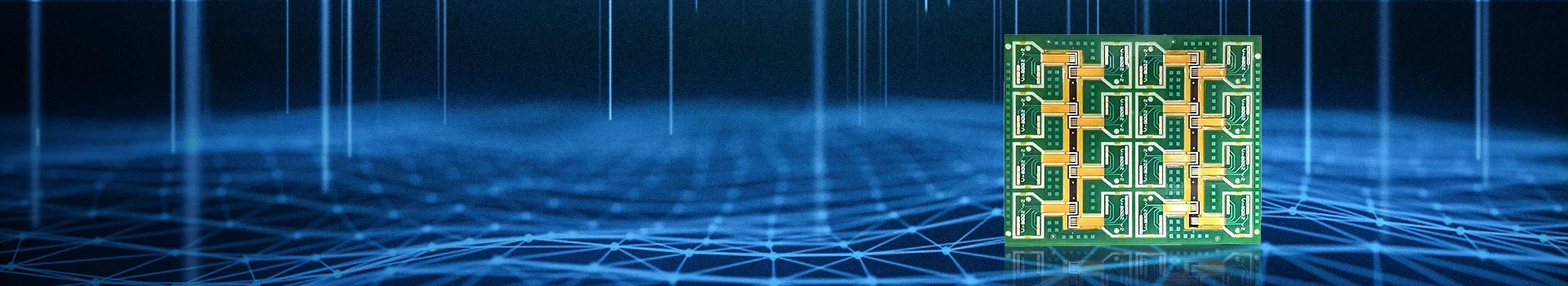

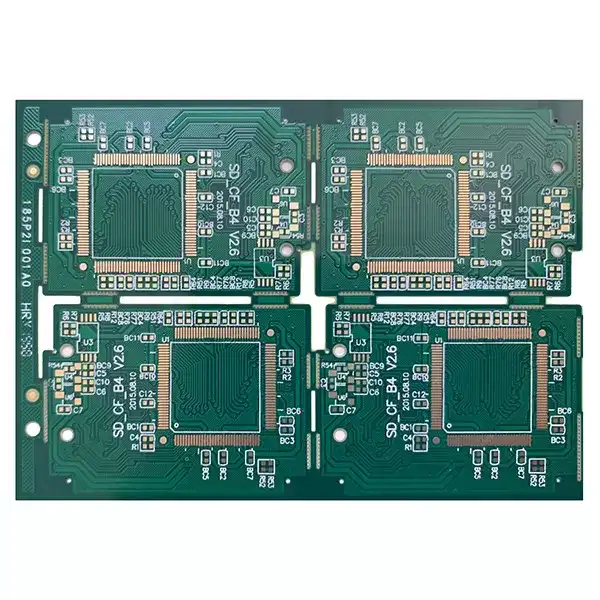

10-layer Rigid immersion gold PCB

Name: 10-layer immersion gold PCB

Layers: 10 layers

Material: FR4 High TG

Finished plate thickness: 1.6mm

Finished copper thickness: Immersion Gold (ENIG)

Finished Copper Thickness: 1/1/1/1/1/1/1/1/1/1 oz

Special Process:

Minimum line width 3.5mil

Hole wall thickness 25um

Small BGA Rigid Printed Circuit Boards

Name: Small BGA circuit board PCB

Layers: 4 layers

PCB Material: FR4 TG170

PCB thickness: 1.6mm

Surface treatment: Immersion Gold ENIG(Gold thickness 2u”)

Finished Copper Thickness: 1/1/1/1 OZ

Solder Mask Ink: Green, Sun PSR-4000

Special Process:

Minimum line width and line spacing: 0.07/0.09mm

BGA pad: 0.25 mm

Rigid immersion gold PCB board

Name: Immersion Gold Plate

Layers: 4 layers

Material: FR4

Finished plate thickness: 1.6mm

Surface treatment: Immersion Gold (ENIG)

Finished Copper Thickness: 1/1/1/1 oz inside and outside

Name: Small BGA circuit board

Material: FR4 High TG

Finished plate thickness: 1.6mm

Surface treatment: Immersion Gold (ENIG)

Finished Copper Thickness: 1/1 oz inside and outside

Special Process:

BGA pad 0.1mm

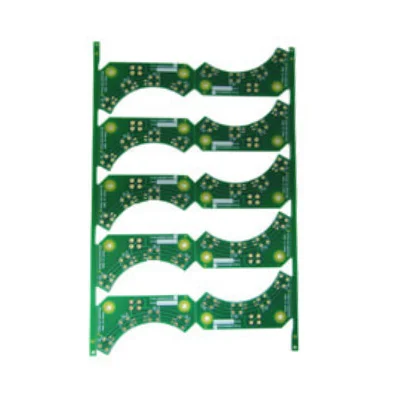

Green oil Rigid Printed Circuit Boards

Name: Green Oil PCB

Layers: 2 layers

Material: FR4 TG150

Finished plate thickness: 1.6mm

Surface treatment: Immersion Gold (ENIG)

Finished Copper Thickness: 1/1 oz inside and outside

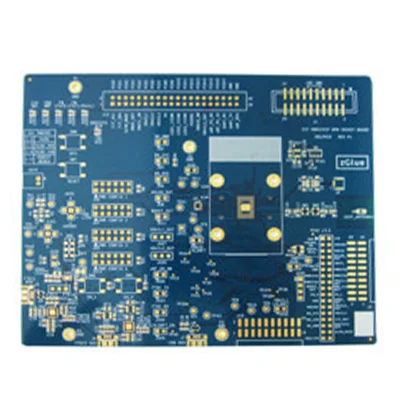

6-layer blue oil immersion gold PCB board

Name: 6-layer blue oil immersion gold plate

Layers: 6 layers

Material: FR4 TG170

Finished plate thickness: 1.6mm

Surface treatment: Immersion Gold (ENIG)

Finished Copper Thickness: 1/1/1/1/1/1 oz inside and outside

- Rigid Printed Circuit Capability

- PCB manufacturing equipment

Introducing Rigid Printed Circuit Boards (PCBs), the go-to solution for reliable and high-performance electronic circuits. These PCBs are designed with rigid substrates, offering stability, durability, and excellent electrical performance. Rigid PCBs are widely used in various industries, from consumer electronics to automotive and industrial applications.

Our Rigid PCBs are manufactured using top-grade materials and state-of-the-art techniques, ensuring exceptional quality and consistency. With precise trace routing and optimized layer stack-up, these PCBs deliver excellent signal integrity and impedance control.

The rigid nature of these PCBs provides structural integrity, making them suitable for applications where components need to be securely mounted. Whether you’re building a smartphone, a medical device, or a control system.

With our Rigid PCBs, you benefit from efficient assembly processes, as the rigid substrate allows for easy automated assembly and soldering. This also reduces production time and cost, making Rigid PCBs a cost-effective solution for large-scale manufacturing.

The capabilities of rigid printed circuit boards (PCBs) can vary depending on the specific manufacturer and their equipment, expertise, and production processes. However, here are some common capabilities associated with rigid PCB manufacturing:

- Layer count: Rigid PCBs can be manufactured with single-sided, double-sided, or multilayer configurations. The layer count depends on the complexity of the circuit design and the requirements of the application. Multilayer PCBs can provide increased functionality and density.

- Material selection: Rigid PCBs are typically made using rigid substrate materials such as FR-4 (a flame-retardant glass epoxy laminate) or other specialized materials like metal-core PCBs for better thermal management. The choice of material depends on factors such as electrical properties, thermal performance, and application requirements.

- Copper weight and thickness: Rigid PCBs can be fabricated with different copper weights and thicknesses to accommodate various current-carrying capacities and design considerations. Common copper weights include 0.5 oz, 1 oz, 2 oz, and higher, depending on the requirements.

- Circuit trace width and spacing: Rigid PCB manufacturers can produce circuit traces with precise widths and spacing to meet specific design requirements. The capabilities for trace width and spacing depend on the manufacturing processes and equipment used by the manufacturer.

- Surface finishes: Rigid PCBs can be finished with various surface treatments to protect the copper traces and enhance solderability. Common surface finishes include Electroless Nickel Immersion Gold (ENIG), HASL (Hot Air Solder Leveling), OSP (Organic Solderability Preservatives), and Immersion Tin or Silver.

- Solder mask and legend printing: Rigid PCBs can have solder mask coatings applied to protect the copper traces and prevent solder bridges during assembly. Legend printing is the process of adding component designators, logos, and other identifying marks to the board for assembly and troubleshooting purposes.

- Panelization and routing: Rigid PCB manufacturers can panelize multiple PCBs on a single panel for efficient production. They can also provide routing services to separate the individual PCBs from the panel while ensuring clean and accurate cuts.

- Quality control and testing: Reputable rigid PCB manufacturers have robust quality control processes in place to ensure that each board meets the specified requirements. They may conduct various tests, including electrical continuity testing, impedance testing, and dimensional checks, to verify the integrity and performance of the PCBs.

Advantages:

- Excellent Electrical Performance: Rigid PCBs also offer superior signal integrity and impedance control, ensuring reliable and high-quality performance of electronic circuits.

- Structural Stability: The rigid substrate of these PCBs provides stability and structural integrity. It also makes them ideal for applications where components need to be securely mounted.

- Ease of Assembly: Rigid PCBs also allow for efficient automated assembly processes, reducing production time and cost.

- Wide Range of Applications: Rigid PCBs are versatile and find applications in various industries. It also includes consumer electronics, automotive, aerospace, and industrial sectors.

- High Reliability: These PCBs are known for their durability and long-term reliability. It ensures the smooth operation of electronic devices even under demanding conditions.

| Standard PCB Production Capability | |

| Feature | Capability |

| Quality Grade | Standard IPC 2 |

| Number of Layers | 1 – 32layers |

| Order Quantity | 1pcs – 10,000,000 pcs |

| Build Time | 2days – 5weeks (Expedited Service) |

| Material | FR-4 Standard Tg 150°C, FR4-High Tg 170°C, FR4-High-Tg 180°C, FR4-Halogen-free, FR4-Halogen-free & High-Tg |

| Board Size | Min 6*6mm | Max 600*700mm |

| Board size tolerance | ±0.1mm – ±0.3mm |

| Board Thickness | 0.4mm – 3.2mm |

| Board Thickness Tolerance | ±0.1mm – ±10% |

| Copper Weight | 0.5oz – 6.0oz |

| Inner Layer Copper Weight | 0.5oz – 2.0oz |

| Copper Thickness Tolerance | +0μm +20μm |

| Min Tracing/Spacing | 3mil/3mil |

| Solder Mask Sides | As per the file |

| Solder Mask Color | Green, White, Blue, Black, Red, Yellow |

| Silkscreen Sides | As per the file |

| Silkscreen Color | White, Blue, Black, Red, Yellow |

| Surface Finish | HASL – Hot Air Solder Leveling |

| Lead Free HASL – RoHS | |

| ENIG – Electroless Nickle/Immersion Gold – RoHS | |

| ENEPIG – Electroless Nickel Electroless Palladium Immersion Gold – RoHS | |

| Immersion Silver – RoHS | |

| Immersion Tin – RoHS | |

| OSP -Organic Solderability Preservatives – RoHS | |

| Min Annular Ring | 3mil |

| Min Drilling Hole Diameter | 6mil, 4mil-laser drill |

| Min Width of Cutout (NPTH) | 0.8mm |

| NPTH Hole Size Tolerance | ±.002″ (±0.05mm) |

| Min Width of Slot Hole (PTH) | 0.6mm |

| PTH Hole Size Tolerance | ±.003″ (±0.08mm) – ±4mil |

| Surface/Hole Plating Thickness | 20μm – 30μm |

| SM Tolerance (LPI) | .003″ (0.075mm) |

| Aspect Ratio | 1.10 (hole size: board thickness) |

| Test | 10V – 250V, flying probe or testing fixture |

| Impedance tolerance | ±5% – ±10% |

| SMD Pitch | 0.2mm(8mil) |

| BGA Pitch | 0.2mm(8mil) |

| Chamfer of Gold Fingers | 20, 30, 45, 60 |

| Other Techniques | Gold fingers |

| Blind and Buried Holes | |

| peelable solder mask | |

| Edge plating | |

| Carbon Mask | |

| Kapton tape | |

| Countersink/counterbore hole | |

| Half-cut/Castellated hole | |

| Press fit hole | |

| Via tented/covered with resin | |

| Via plugged/filled with resin | |

| Via in pad | |

| Electrical Test | |

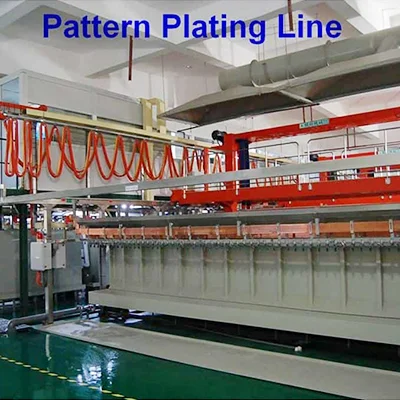

PCB Drilling machine

PCB pattern plating line

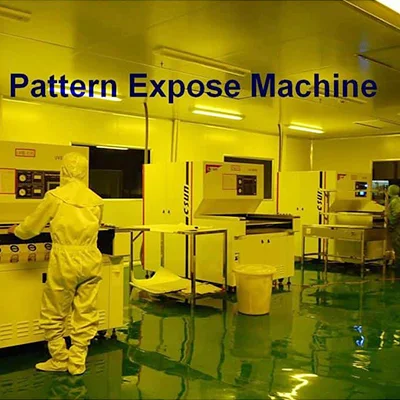

PCB solder mask expose machine

PCB pattern expose machine

Strip film etching line

Solder mask screen silk print machine

Solder mask scrubbing line

PCB Flying Probe Test (FPT)

Fully automatic exposure machine