8 Layer Rigid-flex Assembly by Leadsintec

Name: 8 Layer Rigid-flex Assembly by Leadsintec

Origin: china

Certified: UL, CE, RoHS

layers: 1-40 layers

Surface finish: ENIG/HASL/immersion Tin/ immersion Silver/ Hard Gold

Material: Shengyi/ Panasonic/ Durpont/TEQ/TAIFlex

Solder mask :green,blue, white, red, etc

7 Layer Rigid-flex PCB Assembly by Leadsintec

Name: 7 Layer Rigid-flex PCB Assembly by Leadsintec

Origin: china

Certified: UL, CE, RoHS

Surface finish: ENIG/HASL/immersion Tin/ immersion Silver/ Hard Gold

Material: Shengyi/ Panasonic/ Durpont/TEQ/TAIFlex

Solder mask :green, blue, white, red, etc

Board thickness: customized

6 Layer Rigid-flex Assembly by Leadsintec

Name: 6 Layer Rigid-flex Assembly by Leadsintec

Origin: china

Certified: UL, CE, RoHS

Board thickness: customized

Surface finish: ENIG/HASL/immersion Tin/ immersion Silver/ Hard Gold

Material: Shengyi/ Panasonic/ Durpont/TEQ/TAIFlex

Solder mask :green,blue, white, red, etc

Multi-Layerd Rigid-flex PCB Assembly -Leadsintec

Name: Multi-Layerd Rigid-flex PCB Assembly -Leadsintec

Origin: China

Certified: UL, CE, RoHS

Layer Count: 1 – 30 Layers

Surface Treatment: ENIG, Flash Gold, Hard Gold Finger, Gold Plating(50mil), Gold Finger, Selected Gold Plating, ENEPIG, ENIPIG

Board thickness: customized

Soldermask color: typically white, for aesthetic purposes

Surface finish: HASL/ lead-free HASL

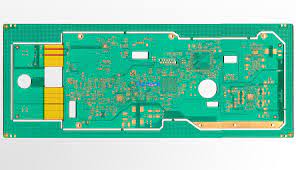

Rigid-flex PCB Assembly Electronic Mother Board

Name: Rigid-flex PCB Assembly Electronic Mother Board

Origin: China

Certified: UL, CE, RoHS

Layer count: 1-18 layers

Material: fr4,Tg=135,150,170,180,210,cem-3,cem-1,al base,rogers,nelco

Board thickness: customized

Soldermask color: typically white, for aesthetic purposes

Surface finish: HASL/ lead-free HASL

OEM Rigid-flex PCB Assembly Manufacturer

Name: OEM Rigid-flex PCB Assembly Manufacturer

Origin: China

Certified: UL, CE, RoHS

Base Material: FR4+PI

Board thickness: customized

Soldermask color: typically white, for aesthetic purposes

Surface finish: HASL/ lead-free HASL

Application: Electronics Devices

- PCB Assembly Capability

- PCB Assembly Equipment

The Rigid-Flex PCB Assembly is a cutting-edge solution that combines the benefits of rigid and flexible printed circuit boards (PCBs) into a single, versatile design. With our advanced assembly capabilities, we can bring your complex and space-constrained electronic designs to reality with utmost precision.

Our skilled technicians excel at handling the intricacies of Rigid-Flex PCB Assembly, seamlessly integrating rigid and flexible sections to create a durable and reliable circuit board. Whether you require a multi-layered design or a custom-shaped PCB, we have the expertise to meet your specific requirements.

Advantages of Rigid-Flex PCB Assembly:

- Space optimization: Rigid-Flex PCBs allow you to maximize space utilization within your electronic devices. By eliminating the need for bulky connectors and cables, you can achieve compact designs, enabling sleeker and more portable products.

- Enhanced reliability: Rigid-Flex PCBs are highly resistant to mechanical stress, vibrations, and thermal fluctuations, making them ideal for applications where durability is crucial. The integrated flexible sections offer improved flexibility, reducing the risk of solder joint fatigue and enhancing the board’s overall reliability.

- Design versatility: Rigid-Flex PCBs offer unmatched design flexibility. They can be shaped and bent to fit into non-planar surfaces, enabling innovative and unconventional product designs. This versatility opens up new possibilities for engineers and designers seeking to push the boundaries of product development.

- Simplified assembly: With Rigid-Flex PCB Assembly, the need for interconnecting cables and connectors is significantly reduced, simplifying the assembly process. This leads to faster production cycles and lowers the chances of errors, ensuring efficient and streamlined manufacturing.

- Cost-effectiveness: Despite their advanced capabilities, Rigid-Flex PCBs can often reduce overall manufacturing costs. By eliminating additional components and simplifying assembly, you can save on materials, labor, and assembly time, resulting in a cost-effective solution.

| SMT capacity: 19 million points/day | ||

| Testing Equipment | X-RAY Nondestructive Tester, First Piece Tester, AOI Automatic Optical Tester, ICT Tester, BGA Rework Station | |

| Placement speed | Chip placement speed (at best conditions) 0.036 S/piece | |

| Mounted Component Specifications | Pasteable smallest package | |

| Minimum device accuracy | ||

| IC type chip accuracy | ||

| Mounted PCB Specifications | Substrate size | |

| Substrate thickness | ||

| throw rate | 1. Resistance-capacitance ratio 0.3% | |

| 2. IC type without throwing material | ||

| Board Type | POP/common board/FPC/rigid-flex board/metal substrate | |

| DIP daily production capacity | ||

| DIP plug-in production line | 50000 points/day | |

| DIP post welding production line | 20000 points/day | |

| DIP test production line | 50000pcs PCBA/day | |

| Assembly processing capability | ||

| The company has more than 10 advanced assembly production lines, dust-free and anti-static air-conditioning workshop, TP dust-free workshop, equipped with aging room, test room, functional test isolation room, advanced and perfect equipment, can carry out various product assembly, packaging, testing, Aging, etc. production. Monthly production capacity can reach 150,000 to 300,000 sets/month | ||

| PCBA processing capability | ||

| project | Mass processing capability | Small batch processing capability |

| Number of layers (max) | 2-18 | 20-30 |

| Plate type | FR-4, Ceramic Sheet, Aluminum Base Sheet PTFE, Halogen Free Sheet, High Tg Sheet | PTFE, PPO, PPE |

| Rogers,etc Teflon | E-65, ect | |

| Sheet mixing | 4 layers – 6 layers | 6th floor – 8th floor |

| biggest size | 610mm X 1100mm | / |

| Dimensional Accuracy | ±0.13mm | ±0.10mm |

| Plate thickness range | 0.2mm–6.00mm | 0.2mm–8.00mm |

| Thickness tolerance ( t≥0.8mm) | ±8% | ±5% |

| Thickness tolerance (t<0.8mm) | ±10% | ±8% |

| Media thickness | 0.076mm–6.00mm | 0.076mm–0.100mm |

| Minimum line width | 0.10mm | 0.075mm |

| Minimum spacing | 0.10mm | 0.075mm |

| Outer copper thickness | 8.75um–175um | 8.75um–280um |

| Inner layer copper thickness | 17.5um–175um | 0.15mm–0.25mm |

| Drilling hole diameter (mechanical drill) | 0.25mm–6.00mm | 0.15mm–0.25mm |

| Hole diameter (mechanical drill) | 0.20mm–6.00mm | 0.10mm–0.20mm |

| Hole Tolerance (Mechanical Drill) | 0.05mm | / |

| Hole tolerance (mechanical drill) | 0.075mm | 0.050mm |

| Laser Drilling Aperture | 0.10mm | 0.075mm |

| Plate thickness aperture ratio | 10:1 | 12:1 |

| Solder mask type | Photosensitive green, yellow, black, purple, blue, ink | / |

| Minimum Solder Mask Bridge Width | 0.10mm | 0.075mm |

| Minimum Solder Mask Isolation Ring | 0.05mm | 0.025mm |

| Plug hole diameter | 0.25mm–0.60mm | 0.60mm-0.80mm |

| Impedance tolerance | ±10% | ±5% |

| Surface treatment type | Hot air leveling, chemical nickel gold, immersion silver, electroplated nickel gold, chemical immersion tin, gold finger card board | Immersion Tin, OSP |

Automatic Solder Paste Printing Machine

AOI Optical Inspection

Smt High-Speed Placement Machine

Nitrogen Reflow Soldering

X-Ray

Three Anti-Paint Spraying Machine

SPI Solder Paste Thickness Tester

Automatic Wave Soldering Machine

First Article Inspection