Solar Hybrid Inverter PCB Board-Leadsintec

Name: Solar Hybrid Inverter PCB Board-Leadsintec

Origin: China

Certified: UL, CE, RoHS

Material: FR4, high TG, halogen-free, high frequency

Surface treatment: HASL/Immersion gold/Immersion silver/Immersion tin

PCB solder mask: White, Black, Yellow, Green, Red, Blue

Application: Consumer Electronics/Home Appliances/Medical equipment

what does Solar Hybrid Inverter PCB Board?

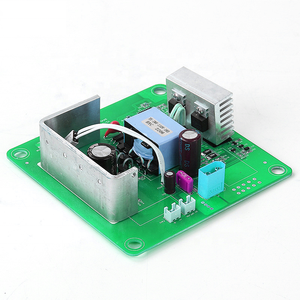

Solar Hybrid Inverter PCB Board often called a printed circuit board, is a crucial part. The PCB board serves as the focal point connecting numerous electronic parts and managing the inverter’s overall operation. A solar hybrid inverter’s main purpose is to change the DC electricity produced by solar panels into AC power, which may be utilized to run electrical devices such as home appliances and other equipment. A battery storage system may also be coupled to a solar hybrid inverter in order to store excess energy for later consumption or to provide backup power during grid interruptions.

What is the main purpose of Solar Hybrid Inverter PCB Board?

- A solar hybrid inverter’s PCB board generally comprises of many layers of insulating materials and conductive copper lines. Various electronic components, including microcontrollers, power transistors, capacitors, transformers, and other circuitry necessary for the operation of the inverter, are routed and connected using these layers.

- The PCB board is essential to the solar hybrid inverter’s effective and dependable operation. It offers the required electrical connections between various components, enabling smooth communication and cooperation between them. The PCB board’s design and layout are optimized to reduce electrical losses, heat dissipation, and electromagnetic interference, improving the inverter system’s overall performance.

- The majority of the time, solar hybrid inverter manufacturer, Leadsintec, create our own PCB board designs based on their unique needs and technological advancements. These designs may differ based on system characteristics such as the inverter’s power capability, the type of solar panels being used, the existence of battery storage, and other elements.

- It’s important to note that the creation of a Solar Hybrid Inverter PCB Board necessitates specialized training in electronics and PCB design. Therefore, it is advised to seek the advice of a professional firm, such as Leadsintec, that specializes in solar power systems and electronics, if you’re wanting to construct or repair a solar hybrid inverter.

Why Leadsintec top manufacturer of Solar Hybrid Inverter PCB Board?

- Since Leadsintec is a top manufacturer, it is probable that we have experience creating PCB boards that are especially suited for solar hybrid inverters. To guarantee the effective and dependable operation of the inverter system, we have expertise dealing with the required components, including microcontrollers, power transistors, capacitors, and transformers. Our cutting-edge technology assures that they can function in a variety of climatic situations, and we are intended to decrease and regulate the power losses connected with solar energy systems.

- Every order you place with Leadsintec is checked. This is a great solution for low-volume production runs and PCB prototyping, as well as for double-checking your files before manufacturing. We double-check every aspect of your BOM (Bill of Materials) and Gerber files so that you may fix any errors before production starts, so saving a lot of time and money and preventing needless repetitions of the prototype assembly process.

- We fully comprehend the needs and business practises of our international clients. As a result, we created our own ideal system for company growth, engineering design, creating artwork, production, and quality control.