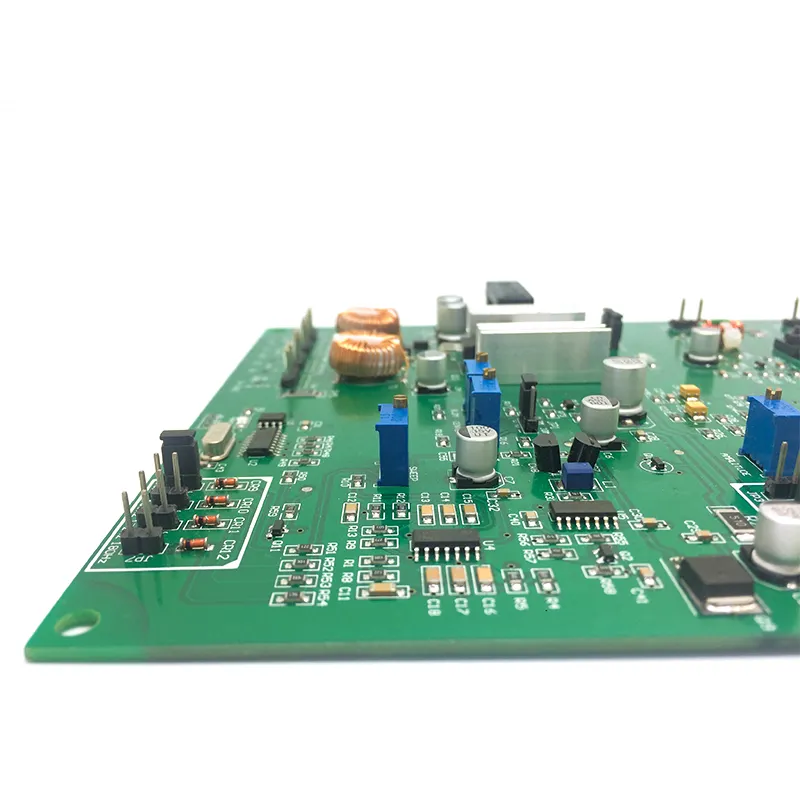

Single Double Sided Reflow SMT Soldering

Name: Single Double Sided Reflow SMT Soldering

Origin: China

Certified: UL, CE, RoHS

surface finishing: HASL, HAL-LF, OSP, ENIG

solder mask: green, blue, white, black, grey, red, yellow, purple

material: FR4/Aluminum

What does PCB Single Double Sided Reflow SMT Solder Mean?

- Using a Single Double Sided Reflow SMT Copper Clad surface mount technology (SMT) soldering is the process of attaching components to a printed circuit board (PCB). SMT soldering is a frequently employed technique for joining electronic parts to a PCB.

- It entails mounting surface-mount components on the board before employing a reflow method to solder them. Most of the time, the components are tiny and have bottom-mounted metal leads or pads that may be soldered straight to the copper traces on the circuit board.

Facts about Single Double Sided Reflow SMT Soldering PCB:

- The components are positioned and soldered on one side of the PCB when using single-sided reflow SMT soldering. This implies that the board’s opposite side is normally left blank or could include through-hole components or other features, whereas the copper traces and components are only present on one side. The components are positioned and soldered on both sides of the PCB when using double-sided reflow SMT soldering.

- This implies that both the top and bottom sides of the board may have copper traces and components. Since both sides of the board may be used, double-sided reflow SMT soldering enables more compact designs and improved component density.

- In a copper-clad PCB, a layer of copper foil is bonded to one or both sides of the base material, often a non-conductive substrate like fiberglass or epoxy.

- The conductive layer for electrical signal routing on the PCB is copper foil. The circuit’s copper-clad PCB facilitates the electrical connections between components and permits power flow and signals.

What PCB Single Double Sided Reflow SMT Soldering Applications?

The electronics industry uses single- and double-sided reflow surface mount technology (SMT) soldering on copper-clad printed circuit boards (PCBs) for various purposes. Here are a few frequent uses:

-

Electronics for the general public:

Single Double Sided Reflow SMT Copper Clad is widely used in electronic goods for the general public, including mobile phones, tablets, computers, televisions, audio systems, gaming consoles, and wearable technology. These PCBs offer the circuitry required for several operations, including connection, signal processing, and power management.

-

Industrial Electronics:

Single and double-sided reflow SMT PCBs is used in several industrial electronic devices, including control systems, automation gear, data loggers, and measuring instruments. The precise control, monitoring, and data processing needed for industrial applications is made possible by these PCBs.

-

Automotive Electronics:

For various functionality, automotive electronics rely on reflow SMT soldering on copper-clad PCBs. These PCBs are used in various devices. It includes lighting controls, infotainment systems, navigation systems, and driving assistance systems.

-

LED Lighting:

LED lighting systems use single- and double-sided reflow SMT soldering to drive and operate LED modules. These PCBs provide the circuitry needed for power conversion, dimming control, and thermal management in LED lighting applications.