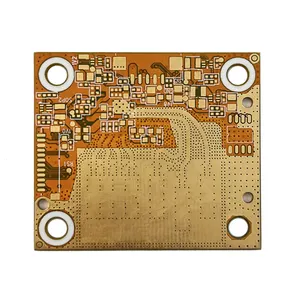

Hybrid PCB Assembly Material Rogers RO3003 and TUC TU827

Name: Hybrid PCB Assembly Material Rogers RO3003 and TUC TU827

Origin: China

Certified: UL, CE, RoHS

Base Material: FR-4/aluminum/ceM-1/cem-3/FR-1

Copper Thickness: 1oz

Surface Finishing: HASL Lead Free

Layer: 1~16 Layers

Solder mask: green, yellow, blue, white, black, Nanya & Taiyo, LPI& mat red,

What is Hybrid PCB Assembly Material Rogers RO3003?

Hybrid PCB Assembly Material Rogers RO3003 is becoming more and more crucial for many electrical designs and applications. Rogers RO3003 is a ceramic-filled, thermally conductive material, making it a good choice for multi-chip module (MCM) applications. The material is a fantastic option for high-performance and miniature designs because of its outstanding electrical characteristics, exceptional thermal stability, and low dielectric constant. Due to many advantages, it is frequently used for hybrid PCB construction in situations where high-frequency signal transmission and RF/microwave circuits are necessary. Many high-frequency applications have employed hybrid PCB assembly material.

Understanding Rogers RO3003’s Advantages for Hybrid PCB Assembly:

In hybrid PCB (Printed Circuit Board) assembly, Rogers RO3003 is a high-frequency laminate material frequently used for RF/microwave circuits and applications requiring high-speed signal transmission. It is a popular option in these applications due to its many advantages. The following are some of Hybrid PCB Assembly Material Rogers RO3003 main benefits:

-

Low Dielectric Loss:

The RO3003 displays less energy loss when transmitting high-frequency signals thanks to its low dielectric loss tangent. This property promotes effective signal transmission, lowers signal attenuation, and aids in preserving signal integrity across the PCB.

-

High Thermal Conductivity:

The laminate material has superb thermal conductivity characteristics that enable it to efficiently disperse heat. This function is vital in high-power applications where heat management is necessary to avoid thermal problems that can impair the performance or dependability of circuits.

-

Outstanding Electrical Performance:

The RO3003 has excellent electrical performance across a broad frequency range, making it appropriate for RF/microwave circuits and applications involving high-frequency communications. Low insertion loss, low dispersion, and regulated impedance are just a few of the robust electrical characteristics it offers, assuring dependable data transmission and upholding signal integrity.

-

Compatibility with Multilayer Structures:

Multilayer PCB designs may readily include the RO3003 into their multilayer structures. It is appropriate for complicated circuit designs needing numerous layers because of its low-profile copper foil, which enables exact control of conductor thickness, impedance matching, and regulated layer-to-layer registration.

Beneficial aspects of Hybrid PCB Assembly Material Rogers RO3003 and TUC TU827:

-

Dimensional Stability:

The substance has exceptional dimensional stability, which means that it keeps its physical characteristics despite changes in external factors like temperature and humidity. For a circuit to operate consistently and to prevent problems like signal distortion or mechanical stress on solder junctions, stability is essential.

-

Process Compatibility:

The RO3003 is capable of being drilled, plated, and soldered during common PCB manufacturing procedures. Assembly takes less time and costs less money thanks to this functionality, which also makes it simple to integrate into current production lines.

-

Reliability:

RO3003 is another product in Rogers’ high calibre line that is noted for its dependability. To ensure consistency, dependability, and long-term performance, it goes through rigorous testing. This dependability is crucial in sensitive applications where a circuit failure might have serious repercussions.