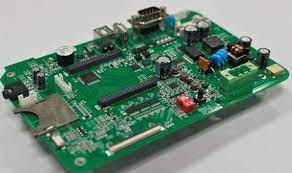

Gaming Console High Volume PCB Assembly

Name: Gaming Console High Volume PCB Assembly

Origin: China

Certified: UL, CE, RoHS

Layers: 1L

Base Material: FR-4

Board Thickness: customized

Copper Thickness: 1oz

Surface Finishing: Lead Free HASL

Application: for gaming

What is Gaming Console High Volume PCB Assembly?

Large-scale production of printed circuit boards is known as game console high-volume PCB assembly. It is an essential step in the process for game console producers that need to swiftly and effectively build many consoles. For a variety of reasons, including cost savings, enhanced quality, and quicker manufacturing, outsourcing this procedure might be advantageous. Outsourcing large-volume PCB assembly for game consoles with the appropriate partner might benefit both the electronics manufacturer and the gaming industry.

Why is High Volume PCB Assembly for Gaming Consoles Ideal for XBOX?

Overall, due to its efficacy, quality control procedures, cost-effectiveness, speed to market, and the knowledge provided by vendors specializing in this field, high-volume PCB assembly is ideally suited for Xbox gaming consoles. Gaming Console High Volume PCB Assembly is a good option for Xbox consoles for several reasons:

-

Manufacturing Efficiency:

Xbox game consoles are well-known gaming devices with a sizable consumer base. High-volume PCB assembly procedures are made to efficiently handle huge numbers of units, resulting in quicker manufacturing and lower cost per unit. Because of this, it is the best option for supplying Xbox consoles.

High-volume PCB assembly procedures are frequently improved for quality control. Any possible flaws or soldering problems can be found using advanced inspection techniques, including automated optical inspection (AOI) and X-ray inspection. This makes sure that every console satisfies the necessary criteria for quality.

-

Cost-Effectiveness:

Because of economies of scale, high-volume production reduces the cost per unit. As a result, the production process as a whole is more economically sound. High-volume PCB assembly enables game console producers like Xbox to build consoles at a reduced cost, which may result in competitive pricing in the market.

-

Speed to Market:

It might be difficult for gaming console makers to satisfy strong demand while abreast of new technical developments. Faster manufacturing cycles made possible by high-volume PCB assembly help businesses like Xbox get their consoles to market quickly and stay one step ahead of the competition.

-

The expertise of the supplier:

High-volume PCB assembly calls for specialized tools and knowledge. The requisite expertise and resources are available from manufacturers specializing in high-volume production to manage the challenges of creating many game consoles. Xbox may use these vendors’ expertise and resources by collaborating with them.

The Benefits of Gaming Console High Volume PCB Assembly:

- Gaming Console High Volume PCB Assembly may be produced more quickly using effective production techniques.

- cost-effectiveness because of economies of scale, which lowers expenses per unit

- procedures to ensure quality, including sophisticated inspection methods like AOI and X-ray inspection

- Rapid time to market allows for fast console supply in response to heavy demand.

- high volume PCB assembly vendors with specialized knowledge

- Streamlined component procurement and assembly processes for improved supply chains

- dependable and consistent products thanks to improved production procedures

- adaptability to changes in design and technical developments

- Through improved production capacities, the game console industry will be more competitive.

- Possibility of competitive price, luring additional people to buy Xbox systems.