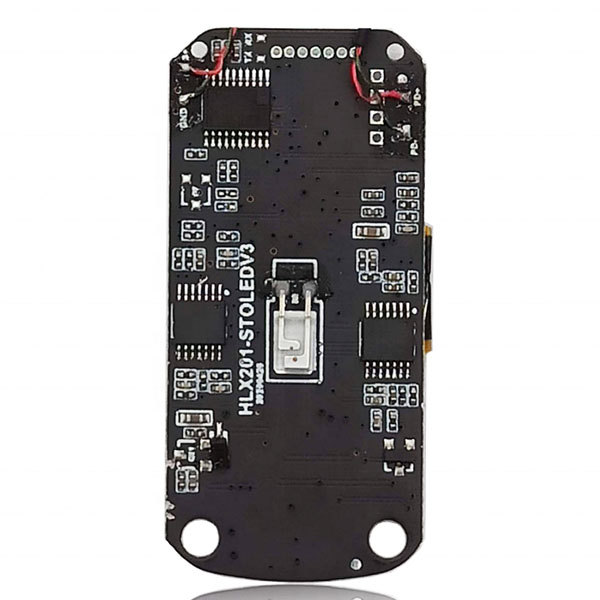

BGA PCB Assembly Factory Manufacture For Pulse Oximeter PCB PCBA one-stop Service

Product Name: PCB Assembly Service

Type: Rigid

Material:FR4, CEM1, CEM3, High Frequency Board,Rogers

Layer:1,2,4,6…20Layer

Shape: Rectangular, Round, Slots, Cutouts, Complex, Irregular

Cutting Shear, V-score, Tab-routed

Board Thickness 0.2-4mm, regular 1.6mm

Copper Thickness:0.5-4oz, regular 1oz

Solder Mask: Green, Red, Blue, Yellow, etc.

Silk Screen: White, Black, etc.

Silk Screen Min Line Width:0.006″ or 0.15mm

Min Trace/Gap:0.1mm or 4mils

Min Drill Hole Diameter 0.01″,0.25mm or 10mils

Surface Finish HASL, ENIG, OSP, etc.

BGA PCB Assembly Factory is a common method used for mounting integrated circuits (ICs) onto PCBs, including those used in pulse oximeters. A pulse oximeter is a medical device used to measure a person’s oxygen saturation levels and pulse rate. Here’s some information regarding BGA PCB assembly for a pulse oximeter:

PCB Design:

-

- The PCB design for a pulse oximeter will include the necessary components such as the BGA ICs, power management, and other supporting circuitry.

- The layout design must also ensure proper signal integrity, power distribution, and thermal management to maintain accurate and reliable operation.

BGA Assembly:

-

- BGA assembly involves attaching the BGA ICs to the PCB using solder balls located on the underside of the IC package.

- The assembly process typically includes the following steps: a. PCB fabrication: The PCB is manufactured with the necessary layers, copper traces, and vias according to the design specifications. b. Solder paste application: Solder paste is applied to the PCB’s BGA pads using a stencil or dispensing equipment. c. BGA placement: The BGA ICs are precisely placed onto the PCB using automated pick-and-place machines. d. Reflow soldering: The PCB is heated in a reflow oven, melting the solder paste and forming reliable solder joints between the BGA balls and also PCB pads.

BGA PCB Assembly Factory Manufacturing Considerations:

-

- BGA assembly requires advanced manufacturing capabilities and equipment to ensure precise placement and accurate soldering.

- Specialized BGA rework and inspection equipment may be necessary for repairing or replacing components, if needed.

- The manufacturing process should adhere to medical device industry standards and also to regulations.

Quality Control and Testing:

-

-

- Rigorous quality control and testing procedures are essential for pulse oximeter production.

- Functional testing, such as verifying sensor accuracy and data acquisition, ensuring display functionality.

- Additional testing, such as electrical testing, environmental testing, and regulatory compliance testing, may also be performed to ensure the pulse oximeter.

-

Product Name: PCB Assembly Service

Type: Rigid

Material:FR4, CEM1, CEM3, High Frequency Board,Rogers

Layer:1,2,4,6…20Layer

Shape: Rectangular, Round, Slots, Cutouts, Complex, Irregular

Cutting Shear, V-score, Tab-routed

Board Thickness 0.2-4mm, regular 1.6mm

Copper Thickness:0.5-4oz, regular 1oz

Solder Mask: Green, Red, Blue, Yellow, etc.

Silk Screen: White, Black, etc.

Silk Screen Min Line Width:0.006″ or 0.15mm

Min Trace/Gap:0.1mm or 4mils

Min Drill Hole Diameter 0.01″,0.25mm or 10mils

Surface Finish HASL, ENIG, OSP, etc.