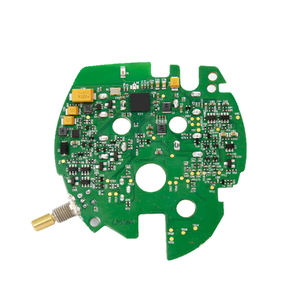

Automtoive Prototype PCB Assembly for Electronic

Name: Automtoive Prototype PCB Assembly for Electronic

Origin: China

Certified: UL, CE, RoHS

Number of Layers: Max 12 layers

Base Material: FR4, FR4/High TG FR-4/M4/ M6/Rogers/Nelco/Isola

Surface Finishing: ENIG,HASL,OSP,ENEPIG

Copper Thickness: 0.5-5oz

Solder Mask Color: Green, Black, Blue, Red, Yellow

What is Automtoive Prototype PCB Assembly?

Manufacturing prototype printed circuit boards (PCBs) for automotive purposes is referred to as Automtoive prototype PCB assembly. Because they provide the necessary foundation for mounting and connecting numerous electronic components, PCBs are essential parts of vehicle electronics.

Creating Your Automotive Ideas into a Prototype PCB Assembly:

An essential phase in the process of making automobile concepts a reality is prototype PCB construction. To construct a working circuit board, electronic components must be manufactured and soldered onto a prototype PCB. This process is known as PCB (Printed Circuit Board) assembly. PCBs are widely utilized in the car industry for many different purposes, including engine control units, sensors, infotainment systems, and more. Follow these general steps to start the prototype PCB assembly process for your vehicle concepts:

-

Design and Layout:

Start by utilizing PCB design software to develop the PCB schematic. Define the components, where they go, and how the traces are routed. Make that the design complies with the dependability, toughness, and safety standards set by the automobile industry.

-

Component Sourcing:

Identify the electronic components needed for your PCB assembly while sourcing components. Consider aspects like temperature range, vibration resistance, and automotive-grade certifications when choosing components for automotive applications. Purchase the components from reputable distributors or vendors.

-

PCB Fabrication:

After the design is finished, utilize a prototyping service or send the PCB design files to a PCB manufacturer. Tell us what you need in terms of board size, thickness, and material. The PCB will be made by the manufacturer in accordance with your design requirements.

-

Placement of Components:

Following receipt of the finished PCBs, it is time to integrate the components into the board. To accomplish this quickly and efficiently, either use automated pick-and-place devices or soldering procedures when doing it manually. Ensure that the components are positioned and aligned correctly.

Automotive Prototype PCB Assembly is Important for High-Quality Vehicle Performance:

Automotive prototype PCB assembly is essential for assuring high-caliber vehicle performance. Printed circuit boards, or PCBs, are crucial parts of contemporary cars since they support a variety of electrical systems. For the vehicle’s electronic parts and circuits, they offer connectivity, organization, and assistance.

- PCBs are made to connect electronic components precisely and securely. A reliable and functioning circuit board is made possible by the assembly process, which guarantees that all the components are positioned and connected appropriately. Loose connections, electrical shorts, and other problems that might affect the operation of the vehicle are less likely with a well-built PCB.

- Within a vehicle, PCBs are in charge of transmitting signals between various electrical systems and components. To guarantee signal integrity, the prototype PCB assembly process takes into account elements including trace routing, impedance management, and grounding approaches. The assembly helps to reduce signal distortion, noise, and electromagnetic interference by optimizing these factors, which improves the overall performance of the vehicle’s electronic systems.

- The fabrication of PCBs using methods and materials appropriate for the automobile sector is ensured by proper prototype PCB assembly. In order to increase the PCB’s resilience to environmental stresses, this involves employing sturdy substrates, conformal coatings, and trustworthy soldering procedures.