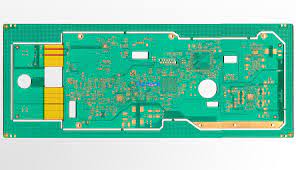

8 Layer Rigid-flex Assembly by Leadsintec

Name: 8 Layer Rigid-flex Assembly by Leadsintec

Origin: china

Certified: UL, CE, RoHS

layers: 1-40 layers

Surface finish: ENIG/HASL/immersion Tin/ immersion Silver/ Hard Gold

Material: Shengyi/ Panasonic/ Durpont/TEQ/TAIFlex

Solder mask :green,blue, white, red, etc

What does an 8 Layer Rigid-Flex PCB Assembly mean?

A printed circuit board (PCB) with eight layers of conductive material and both stiff and flexible parts is referred to as an 8 layer rigid-flex assembly. Multiple layers of an insulating material, such as polyimide (a flexible polymer) or FR-4 (a flame-retardant epoxy-based laminate), make up the PCB. These layers have electrical traces and pads etched onto them. Eight layers of stiff and flexible layers are commonly alternated in an eight-layer rigid-flex PCB.

In contrast to the flexible layers, which enable the board to bend or flex, the rigid layers are built of rigid PCB material. Vias, which are conductive channels that cross through the insulating layers and enable electrical connections between various layers, are used to connect the layers together. These vias allow power and signal transfer between the board’s stiff and flexible parts. Increased routing density, higher signal integrity, and improved noise and interference management are just a few advantages of using many layers.

The Positive Benefits of an Eight Layer Rigid-Flex PCB Assembly:

-

Compact Design:

Compared to boards with fewer layers, an 8-layer rigid-flex PCB allows for a more compact design. It offers more flexibility in signal routing and component placement, which is particularly helpful in situations with limited space.

-

High Density:

The PCB’s eight layers enhance routing density, allowing for the integration of more complicated circuitry and a greater number of components into a smaller space. In situations where miniaturization is a crucial need, this might be useful.

-

Time-to-Market Advantage:

When compared to employing separate stiff and flexible boards, 8 Layer Rigid-flex Assembly enable quicker and more efficient production processes. As a consequence, enterprises may launch their goods faster and gain a competitive advantage by reducing the time-to-market for products made using an 8-layer rigid-flex PCB assembly.

-

Dependability and Sturdiness:

Rigid-flex PCBs are made to tolerate repetitive bending, flexing, and vibration. Signal deterioration and mechanical failure risk are reduced by removing connectors and cutting back on interconnections. Because of this, they are very dependable and strong, making them ideal for applications that need sustained performance in demanding settings. It is appropriate for applications with space restrictions because it enables the integration of complicated circuitry and a larger number of components into a smaller area.

One of the major manufacturers of 8 Layer Rigid-Flex PCB Assembly globally is Leadsintec:

- The goal of Leadsintec is to provide rigid-flex circuit boards swiftly and reliably without compromising quality. Customers that seek just protection from us can engage with our engineering team. The Rigid-Flex PCB Assembly is one of the PCB types we provide. With years of experience in the industry, we have developed competence in making various different types of PCBs.

- Designers, producers, and users may all profit from Rigid-Flex PCB Assembly. This kind of assembly combines the flexibility of a flexible PCB with the stiffness of a regular PCB, enabling more complex designs, more effective routing, and higher dependability. The manufacturer of 8 Layer Rigid-Flex PCB Assembly is Leadsintec. We provide users with a number of benefits, including higher board density, enhanced signal integrity, and less crosstalk. Our benefits enable quicker and more dependable performance.