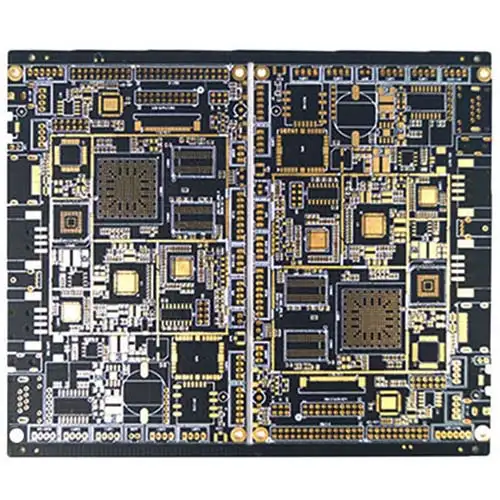

Cooker hood mother board PCB Prototype

Name: Cooker hood mother board PCB

Plate: KB6165G

Plate thickness: 1.6mm

Layers: 2L

Size: 82.63*46.7mm

Minimum aperture: 0.296mm

Line width/moment: 0.342*0.37mm

Copper foil thickness: 1/1OZ

Surface treatment: gold plating process

Solder mask/character: black oil and white characters

Name: hair curler circuit board

Sheet: FR-4

Plate thickness: 1.0mm

Layers: 2L

Size: 76.82*13.6mm

Minimum aperture: 0.32mm

Line width/moment: 0.3*0.41mm

Copper foil thickness: 1/1OZ

Surface Treatment: OSP Antioxidant

Solder mask/character: black oil and white characters

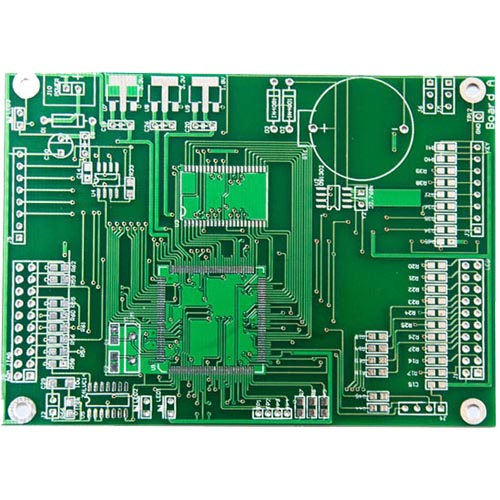

Electric vehicle alarm PCB Prototype

Name: Electric vehicle alarm PCB

Plate: KB6165F

Plate thickness: 1.6mm

Layers: Double-sided

Size: 67*41.37mm

Minimum aperture: 0.33mm

Line width/moment: 0.36*0.44mm

Copper foil thickness: 35um

Surface treatment: lead-free spray tin

Solder mask/character: green oil white character

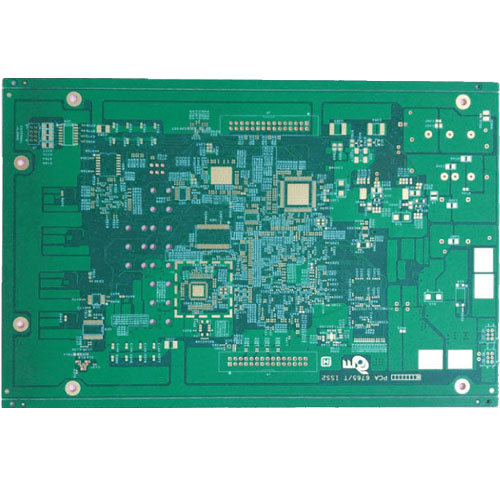

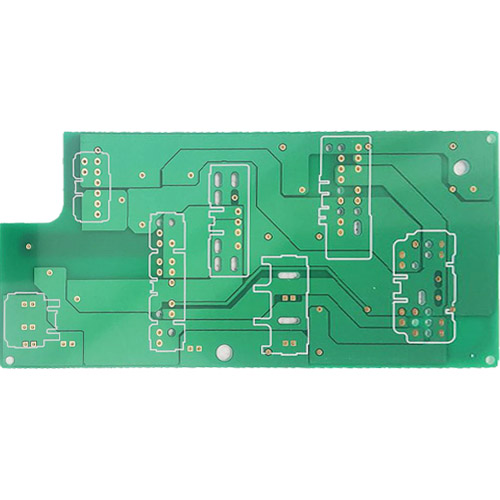

Server Power Backplane PCB Prototype

Name: Server Power Backplane PCB

Plate: KB6167F

Plate thickness: 1.6mm

Layers: 2L

Size: 78.26*61.3mm

Minimum aperture: 0.281mm

Line width/moment: 0.21*0.186mm

Copper foil thickness: 1/1OZ

Surface treatment: lead-free spray tin

Solder mask/character: green oil white character

Electric guitar speaker PCB Prototype

Name: Electric guitar speaker PCB

Sheet: FR-4

Plate thickness: 1.0mm

Layers: 2L

Size: 86.9*73.58mm

Minimum aperture: 0.236mm

Line width/moment: 0.32*0.37mm

Copper foil thickness: 1/1OZ

Surface treatment: lead-free spray tin

Solder mask/character: green oil white character

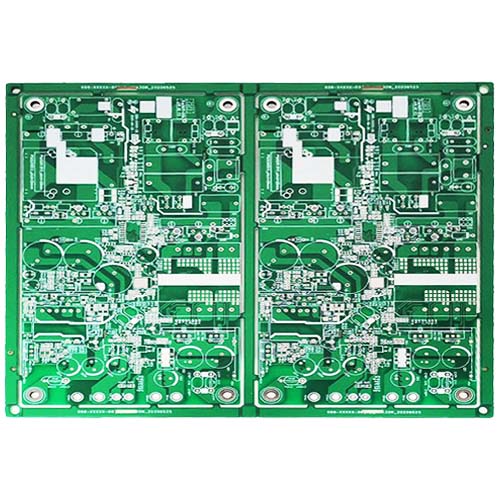

Double-sided through-hole PCB boards

Name: Double-sided through-hole PCB boards

Sheet: FR-4

Plate thICkness: 1.0mm

Layers: 2L

Size: 86.9*73.58mm

Minimum aperture: 0.236mm

Line width/moment: 0.32*0.37mm

Copper foil thickness: 1/1OZ

Surface treatment: lead-free spray tin

Solder mask/character: green oil white character

- PCB Prototype Capability

- PCB manufacturing equipment

Introducing our PCB Prototype, a cutting-edge solution for rapid prototyping and development of electronic circuits. Our PCB Prototype seamlessly integrates with popular design software, making it convenient to transfer your circuit schematics and layout files.

Our dedicated team of experts is ready to assist you throughout the PCB prototyping process. Whether you have technical questions, need design guidance, or require assistance with your order, our knowledgeable support staff is here to help.

Experience the power of our PCB and accelerate your product development journey. From concept to reality, we’re here to provide you with high-quality, fast, and also customizable PCB prototypes that meet your exact specifications.

Advantages of PCB Prototype:

- High-Quality Manufacturing: Our PCB is fabricated using state-of-the-art manufacturing processes and materials. We employ advanced techniques to ensure exceptional quality and reliability in every circuit board produced.

- Quick Turnaround Time: We understand the importance of speed in the product development cycle. With our PCB Prototype, you can expect fast turnaround times. This also allows you to iterate and test your designs quickly. Reduce your time to market and gain a competitive edge.

- Customization Options: Our PCB supports a wide range of customization options to cater to your specific needs. From choosing different board sizes and shapes to selecting the number of layers and solder mask colors, we provide flexibility to tailor the prototype to your requirements.

- High Precision: We utilize cutting-edge equipment and follow stringent quality control processes to achieve high precision in our PCB prototypes. Every component pad, trace, and drill hole is meticulously crafted to ensure accurate and reliable connections, giving you confidence in your designs.

- Compatibility: Our PCB supports compatibility with various electronic components, including through-hole and surface mount devices (SMDs). This versatility also allows you to seamlessly integrate different types of components into your prototypes.

| PCB Prototype Features | Capability |

| Quality Grade | Standard IPC 1-3 |

| Number of Layers | 1 – 32layers |

| Order Quantity | 1pcs + |

| Build Time | 2 – 15 days |

| Material | Rigid: FR2, CEM-1, CEM-3, FR4 (standard – halogen-free – high performance) including ShengYi, Iteq, Elite Materials Corp., NanYa, Kingboard, Grace, TUC, Meteorwave |

| Flex: PI, PET Including Taiflex, Dupont FR & AP, Panasonic, ShengYi, Doosan. Hanwha, SF305 | |

| Metal Core: Metal Core Aluminum based material Including Bergquist MP, HT & CML, ITEQ T-Lam, Laird TLAM SS Taiflex, Dupont FR & AP, Panasonic, ShengYi, Doosan. Arlon,Ventec and suggested local material brand( for detail pls contact our sales) | |

| Board Size | Maximum 610mm*1200mm (24” * 47″”) |

| Board Thickness | Rigid PCB : 0.15mm – 10 mm |

| FLEX PCB: 0.05mm – 0.16mm | |

| Board Thickness tolerance | / |

| Copper Weight | 1.0oz – 15.0oz |

| Inner Layer Copper Weight | 0.5oz – 12.0oz |

| Min Trace/Space( track/gap or width/space) | 2mil/2mil (0.05mm/0.05mm) |

| Solder Mask Color | Green, White, Blue, Black, Red, Yellow or others |

| Silkscreen Color | White, Black or others |

| Surface Finish | ENIG / GF / OSP / I Ag / HASL (lead) / HASL (Leadfree) / Plating Au/Ni/ Immersion Sn / GF+OSP / GF+HASL / OSP+ENIG /IAG+GF/Isn+GF |

| Min Annular Ring | 5mil |

| Min Drilling Hole Diameter | mechanical: 0.1mm |

| laser : 0.05mm | |

| NPTH Hole Size Tolerance | ±0.025mm |

| PTH Hole Size Tolerance | ±.003″ (±0.08mm) – ±.006″ (±0.15mm) |

| Surface/Hole Plating Thickness | 20μm – 30μm |

| SM Tolerance (LPI) | .003″ (0.075mm) |

| Aspect Ratio | 20:1 (board thickness: hole size) |

| Test | 10V – 250V, flying probe or testing fixture |

PCB Drilling machine

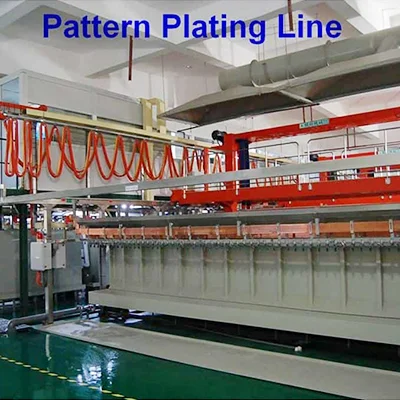

PCB pattern plating line

PCB solder mask expose machine

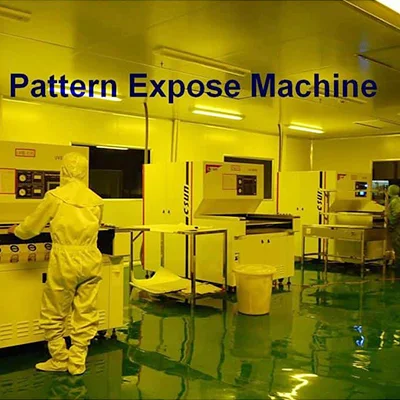

PCB pattern expose machine

Strip film etching line

Solder mask screen silk print machine

Solder mask scrubbing line

PCB Flying Probe Test (FPT)

Fully automatic exposure machine