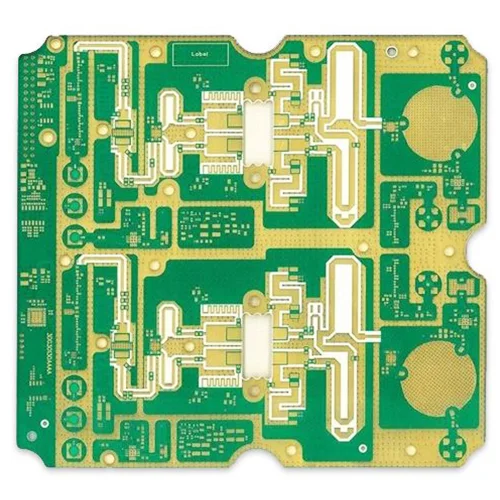

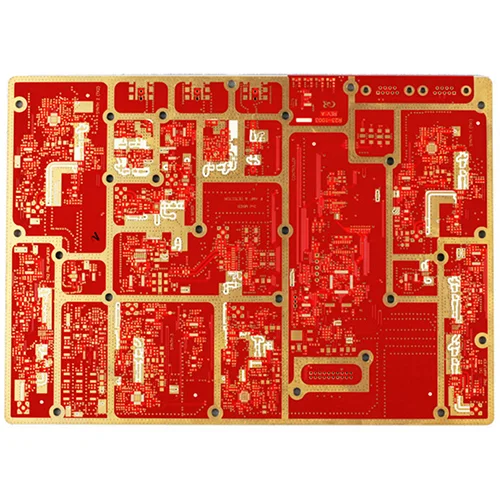

Lightwave Communications PCB Board

Name: Lightwave Communications PCB Board

Layers: 6L

material: TU872+R4350B

Board Thicknes: 1.8 mm

Copper Thicknes: 35/35/35/35um

Smallest Hole Diameter: 0.20mm

Surface Treatment: ENIG(2U”)

Technical Feature: Vacuum Plugging, Blind buried via

Applications

Ground receiving equipment

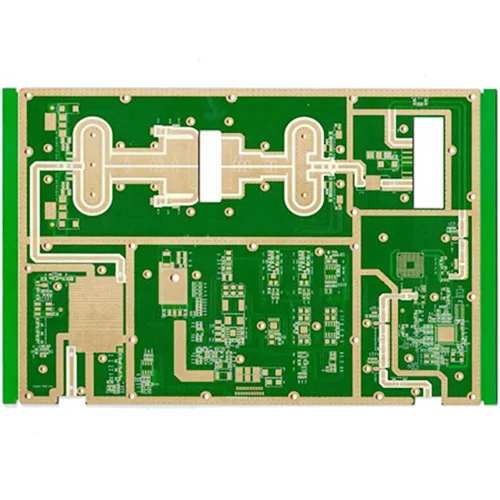

High Frequency Hybrid PCB Board

Product Name: High Frequency Hybrid PCB Board

Plate: Rogers RO4350B+FR4

Layers: 12L

Board Thickness: 1.6MM

Copper thickness: finished copper thickness 1OZ

Impedance: 50 ohm

Medium thickness: 0.508MM

Dielectric Constant : 3.48

Thermal conductivity: 0.69w/m.k

Flame retardant grade: 94V-0

Volume resistivity: 1.2*1010

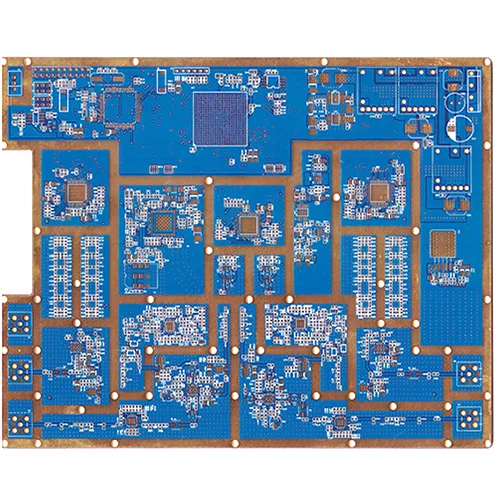

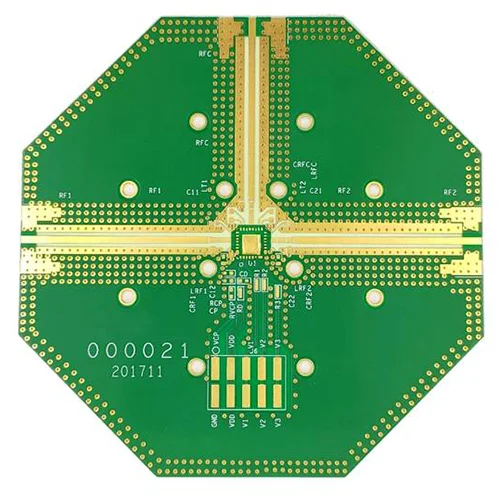

Millimeter wave radar PCB circuit board

Name: Millimeter wave radar PCB circuit board

Plate: Rogers RO3003+370HR

Dielectric constant: high frequency material dielectric constant 3.0

Medium thickness: 5mil (0.127mm)

Number of layers: 6 L

Plate thickness: 1.2mm

Copper Thickness: 1oz for inner and outer layers

Via: Resin plug hole

Surface technology: chemical immersion silver

Thermal conductivity: 0.69w/m.k

Loss: 0.001

Line width: 0.1mm

Line distance: 0.1mm

Blind hole structure: L1-L2, L3-L6

Uses: automotive radar, automotive sensor module

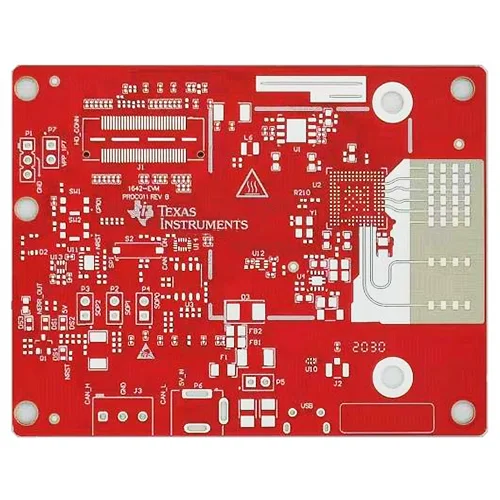

RO4350B + FR4 high frequency hybrid PCB

Product name: RO4350B + FR4 high frequency hybrid plate

Plate: Rogers RO4350B+FR4

Layers: 4L

Board thickness: 1.2MM

Copper Thickness: 1OZ

Media thickness: 0.508mm

Dielectric Constant: 3.48

Thermal conductivity: 0.69w/m.k

Flame retardant grade: V-0

Volume resistivity: 1.2*1010

Surface resistivity: 5.7*109

Density: 1.9gm/cm3

Surface technology: chemical immersion gold

Application: communication instrument

Communication high frequency hybrid PCB

Name: Communication High Frequency Hybrid PCB

Category: RF PCB

PCB layers: 6L

Sheet used: Ro4350B+FR4

Plate thickness: 1.6mm

Size: 210mm*28Omm

Surface Treatment: Immersion Gold

Minimum aperture: 0.25mm

Application field: communication

Features: high frequency mixed pressure

RO4350B+FR4 high frequency hybrid PCB

Name: RO4350B+FR4 High Frequency Hybrid PCB Board

Plate: Rogers RO4350B+FR4

Layers: 4L

Board Thickness: 1.6MM

Copper thickness: finished copper thickness 1OZ

Impedance: 50 ohm

Medium thickness: 0.508MM

Dielectric Constant : 3.48

Thermal conductivity: 0.69w/m.k

Flame retardant grade: 94V-0

Volume resistivity: 1.2*1010

- PCB Capability

- PCB manufacturing equipment

- PCB Materials

Introducing our hybrid PCB solutions, combining the benefits of different PCB technologies to meet the unique requirements of your application. Hybrid PCBs integrate multiple technologies, such as rigid, flex, and rigid-flex PCBs, into a single board, offering versatility, space savings, and enhanced functionality.

Hybrid PCBs undergo rigorous testing and validation processes to ensure reliability and durability. The combination of different technologies is carefully engineered to withstand mechanical stresses, temperature variations, and other environmental factors. This also ensures a long-term performance and product integrity.

Our hybrid PCBs are designed to address complex design challenges, allowing for the integration of different form factors, bending areas, and specialized connectors.

Advantages of Hybrid PCB:

- Integration of Multiple Technologies: Hybrid PCBs allow for the seamless integration of different PCB technologies into a single board. You can combine the rigidity and stability of rigid PCBs with the flexibility and bending capabilities of flex or rigid-flex PCBs, providing design freedom and versatility.

- Space Savings: Hybrid PCBs enable the consolidation of multiple PCBs into a single board, resulting in significant space savings. By integrating different technologies you can optimize the use of available space and reduce overall system size.

- Improved Signal Integrity: Hybrid PCBs offer enhanced signal integrity by allowing for optimized signal routing and impedance control. You can design signal paths to minimize signal loss, crosstalk, and EMI issues, resulting in improved overall system performance and reliability.

- Design Flexibility: With hybrid PCBs, you have greater design flexibility to accommodate complex geometries, irregular shapes, and unique form factors. This flexibility also enables the realization of innovative product designs and the integration of electronics into unconventional shapes or spaces.

- Cost Savings: Hybrid PCBs can provide cost savings by reducing the number of separate PCBs, connectors, and assembly processes required in a system. Additionally, the consolidation of components and optimized board layouts can streamline manufacturing and assembly, reducing overall production costs.

| Item | Capability |

| Layer Count | 1-40layers |

| Base Material | KB、Shengyi、ShengyiSF305、FR408、FR408HR、IS410、FR406、GETEK、370HR、IT180A、Rogers4350B、Rogers4000、PTFE Laminates(Rogers series、Taconic series、Arlon series、Nelco series)、Rogers/Taconic/Arlon/Nelco laminate with FR-4 material(including partial Ro4350B hybrid laminating with FR-4) |

| Board Type | Backplane、HDI、High multi-layer 、blind&buried PCB、Embedded Capacitance、Embedded resistance board 、Heavy copper power PCB、Backdrill. |

| Board Thickness | 0.2-5.0mm |

| Copper Thickness | Min. 1/2 OZ, Max. 10 OZ |

| PTH Wall | 25um(1mil) |

| Maximum Board Size | 1100*500mm(43”*19”) |

| Min laser drilling size | 4mil |

| Min. Spacing/Tracing | 2.7mil/2.7mil |

| Solder Mask | Green, Black, Blue, Red, White, Yellow, Purple matte/glossy |

| Surface Treatment | Flash gold(electroplated gold)、ENIG、Hard gold、Flash gold、HASL Lead-free 、OSP、ENEPIG、Soft gold、Immersion silver、Immersion Tin、ENIG+OSP, ENIG+Gold finger, Flash gold(electroplated gold)+Gold finger, Immersion silver+Gold finger, Immersion Tin+Gold finger. |

| Min. Annular Ring | 3mil |

| Aspect ratio | 10:1(HASL Lead-free 、HASL Lead、ENIG、Immersion Tin、Immersion silver、ENEPIG);8:1(OSP) |

| Impedance control | ±5ohm(<50ohm), ±10%(≥50ohm) |

| Other Techniques | Blind/Buried Via |

| Gold Fingers | |

| Press Fit | |

| Via in Pad | |

| Electrical Test |

PCB Drilling machine

PCB pattern plating line

PCB solder mask expose machine

PCB pattern expose machine

Strip film etching line

Solder mask screen silk print machine

Solder mask scrubbing line

PCB Flying Probe Test (FPT)

Fully automatic exposure machine

| Here there’re many laminate material datasheets, they’re useful and helpful for you, please see them: | ||||||||

| SUPPLIER | PCB LAMINATE | TYPE | MATERIAL DATASHEET | TG | TD | DK(1MHZ) | DK(1GHZ) | DK(10GHZ) |

| KB | KB-6160 | FR4 | DOWNLOAD | 135 | 305 | 4.35 | – | – |

| KB-6160A | FR4 | DOWNLOAD | 135 | 305 | 4.35 | – | – | |

| KB-6160C | FR4 | DOWNLOAD | 135 | 314 | 4.7 | – | – | |

| KB-6150 | FR4 | DOWNLOAD | 132 | 305 | 4.6 | – | – | |

| KB-6150C | ||||||||

| KB-6164 | FR4 | DOWNLOAD | 142 | 330 | 4.8 | – | – | |

| KB-6164F | FR4 | DOWNLOAD | 145 | 340 | 4.8 | – | – | |

| KB-6165F | FR4 | DOWNLOAD | 150 | 346 | 4.8 | – | – | |

| KB-6167F | FR4 | DOWNLOAD | 170 | 349 | 4.8 | – | – | |

| SHENGYI | S1141 | FR4 | DOWNLOAD | 135 | 310 | 4.6 | – | – |

| S1141KF | FR4 | DOWNLOAD | 140 | 350 | 4.7 | – | – | |

| S1000 | FR4 | DOWNLOAD | 155 | 335 | 4.9 | – | – | |

| S1170 | FR4 | DOWNLOAD | 170 | 335 | 4.6 | – | – | |

| S1000-2 | FR4 | DOWNLOAD | 170 | 335 | 4.8 | – | – | |

| S1155 | FR4 | DOWNLOAD | 135 | 370 | 4.7 | – | – | |

| ITEQ | IT-158 | FR4 | DOWNLOAD | 150 | 340 | 4.6-4.8 | – | – |

| IT-180 | FR4 | DOWNLOAD | 180 | 350 | 4.5-4.7 | – | – | |

| TUC | TU-768 | FR4 | DOWNLOAD | 180 | 350 | – | 4.3-4.4 | 4.3 |

| TU-872 | Modified Epoxy | DOWNLOAD | 200 | 340 | – | 3.8-4.0 | 3.8 | |

| ROGERS | RO 3003 | Cer/PTFE | DOWNLOAD | – | 500 | – | – | 3 |

| RO 3010 | Cer/PTFE | DOWNLOAD | – | 500 | – | – | 10.2 | |

| RO 4003 | Hydrocarbon/Cer | DOWNLOAD | >280 | 425 | – | – | 3.38 | |

| RO 4350B | Hydrocarbon/Cer | DOWNLOAD | >280 | 390 | – | – | 3.48 | |

| RT/duroid 5880 | PTFE/Glass | DOWNLOAD | – | 500 | – | – | 2.2 | |

| ISOLA | Polyclad 370HR | FR4 | DOWNLOAD | 170 | 340 | 4.8-5.1 | – | – |

| FR406-HR | FR4 | DOWNLOAD | 190 | 325 | 3.91 | 3.86 | 3.81 | |

| FR408-HR | FR4 | DOWNLOAD | 200 | 360 | 3.72 | 3.69 | 3.65 | |

| P96 | Polyimide | DOWNLOAD | 260 | 416 | – | 3.78 | 3.73 | |

| Hitachi | MCL-BE- 67G | Modified Epoxy | DOWNLOAD | 140 | 340 | 4.9 | 4.4 | – |

| MCL-E-679F | FR4 | DOWNLOAD | 170 | 350 | 4.2-4.4 | 4.3-4.5 | – | |

| MCL-LX-67Y | Special Laminate | DOWNLOAD | 185-195 | 325-345 | – | 3.4-3.6 | – | |

| Nelco | N4000-13 | Modified Epoxy | DOWNLOAD | 210-240 | 365 | – | 3.7 | 3.6 |

| N4000-13EP | Modified Epoxy | DOWNLOAD | 210-240 | 350 | – | 3.4 | 3.2 | |

| N4000-13SI | Modified Epoxy | DOWNLOAD | 210-240 | 350 | – | 3.4 | 3.2 | |

| N4000-13EP SI | Modified Epoxy | DOWNLOAD | 210-240 | 350 | – | 3.4 | 3.2 | |

| Taconic | TLX-6 | PTFE | DOWNLOAD | – | – | – | – | 2.65 |

| TLX-7 | PTFE | DOWNLOAD | – | – | – | – | 2.6 | |

| TLX-8 | PTFE | DOWNLOAD | – | – | – | – | 2.55 | |

| TLX-9 | PTFE | DOWNLOAD | – | – | – | – | 2.45 | |

| RF35 | PTFE | DOWNLOAD | <315 | – | 3.5 | – | 3.5 | |

| TLC-27 | PTFE | DOWNLOAD | – | – | – | – | 2.75 | |

| TLC-30 | PTFE | DOWNLOAD | – | – | – | – | 3 | |

| TLC-32 | PTFE | DOWNLOAD | – | – | – | – | 3.2 | |

| Arlon | Arlon 25N | Cer | DOWNLOAD | 260 | – | – | – | 3.38 |

| Arlon 25FR | Cer | DOWNLOAD | 260 | – | – | – | 3.58 | |

| Arlon 33N | Polymide | DOWNLOAD | >250 | 353 | 4 | – | – | |

| Arlon 35N | Polymide | DOWNLOAD | >250 | 363 | 4.2 | – | – | |

| Arlon 85N | Polymide | DOWNLOAD | 250 | 387 | 4.2 | – | – | |

| Stablcor | ST325 | – | DOWNLOAD | Thermal conductivity:75w/m.k(with 1oz copper) | ||||

| ST10 | – | DOWNLOAD | Thermal conductivity:325w/m.k(with 1oz copper) | |||||

| Panasonic | R-1566W | FR4 | DOWNLOAD | 140 | 330 | 4.95 | 4.7 | 4.65 |

| Ventec | VT-901 | Polymide | DOWNLOAD | 250 | 390 | 4.2-4.5 | 4.0-4.3 | – |

| VT-90H | Polymide | DOWNLOAD | 250 | 390 | 4.2-4.5 | 4.0-4.3 | – | |

| Bergquist | ht-04503 | – | DOWNLOAD | Thermal conductivity:2.2w/m.k(with 1oz copper) | ||||